Fabrication & Construction

RITS ( Fabrication & Construction )

STORAGE TANKS

Cryogenic Double Wall Storage Tanks (Single/Double/Full Containment)

Storage of liquefied gases is inevitable in different plants. Temperature condition and other technical complexities requires special know-how for the design of these storage tanks.

RITS has know-how and experience for design, fabrication, supply and erection of cryogenic storage tanks and related auxiliaries like refrigeration system.

Atmospheric & Low-Pressure Storage Tanks

Storage tanks are an overlooked part of any refinery or chemical plant. They don’t make boatloads of money, but they are an integral part of keeping a process running smoothly and provide a buffer to help minimize lost production and shutdown time. Adequately sizing raw feed, intermediate product, and final product storage tanks should include a number of scenarios which are often overlooked by “rule-of-thumb” type considerations.

RITS design, engineering, fabrication and construction in form of EPC contract are based on latest edition of API-650/620 standards. Knowledgeable experts are able to provide the best technical and cost-efficient proposals to clients, which is completely meets the requirements of the project.

VISCOSIFIERS/SUSPENDING AGENTS

Pressure Vessels, Drums, Spherical Tanks, Towers & Reactors

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure, these kinds of equipment are designed according to ASME standards. ACGC’s experts on design and fabrication of pressure vessels are following the ASME standards accurately for improving service life of pressure vessels. Some ACGC’s products are including Pressure Vessels,

Drums, Spherical Tanks, Towers and Reactors that have been produced with rolled cylindrical/spherical shells, elliptical/ hemispherical/ conical heads or sections, skirt/leg/lug/ring/saddle supports, nozzle

pipes, opening & connections, girth flanges, accessories and so forth, therefore a lot of facilities are ready for fabricating every type of pressure vessel.

Air Cooled Heat Exchangers

Air cooled heat exchangers are commonly used in industrial applications where a reliable source of water is not available as a cooling medium. Air cooled steam condensers are a special type of heat exchanger employed to condense steam at the exhaust end of a steam turbine for both power generation and mechanical drive applications.

The hot process fluid to be cooled flows through finned tubes while the cooling air flows across the outer surface to remove

heat. The cooling air is propelled by fans in either a forced draft or induced draft configuration. Mechanical designs can conform to international standards and codes including:

ASME Section VIII, Division 1

API 661/ISO 13706

TEMA, when applicable

With our vast knowledge and expertise in a wide range of industries and markets we can help our client in the most cost effective and efficient options available.

Shell & Tube Heat Exchangers

A shell and tube heat exchanger is a class of heat exchanger designs. It is the most common type of heat exchanger in oil refineries and other large chemical processes and is suited for higher-pressure applications. This type of heat exchanger consists of a shell (a large pressure vessel) with a bundle of tubes inside it. One fluid runs through the tubes, and another fluid flows over the tubes (through the shell) to transfer heat between the two fluids. The set of tubes is called a tube bundle, and may be composed of several types of tubes: plain, longitudinally finned, etc.

Flare System

Flares are important safety devices used in refineries and petrochemical facilities. They safely burn excess hydrocarbon gases which cannot be recovered or recycled. During flaring, excess gases are combined with steam and/or air and burnt off in the flare system to produce water vapor and carbon dioxide. Gas flaring is a significant source of greenhouse gases emissions. It also generates noise, heat and provided large areas uninhabitable.

ACGC with the cooperation of well-known international companies have consolidated experiences in engineering, supply and management of flare system projects including process design, mechanical design and engineering, material supply and eventually manufacturing in our workshop.

Vent Stack (Cold Flare)

Vent disposal system collects and discharges gas from atmospheric or pressurized process components to the atmosphere to safe locations for final release during normal operations and abnormal conditions (emergency relief).

In vent systems, the gas exiting the system is dispersed in the atmosphere.

VISCOSIFIERS/SUSPENDING AGENTS

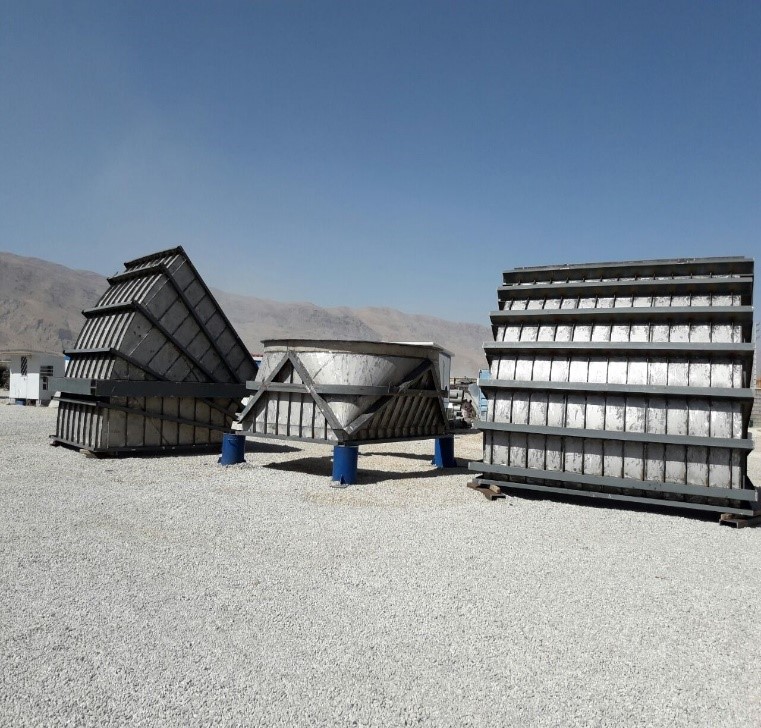

Bin, Hopper, Silo & Rectangular Tanks

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure, these kinds of equipment are designed according to ASME standards. ACGC’s experts on design and fabrication of pressure vessels are following the ASME standards accurately for improving service life of pressure vessels. Some ACGC’s products are including Pressure Vessels, Drums, Spherical Tanks, Towers and Reactors that have been produced with rolled cylindrical/spherical shells, elliptical/ hemispherical/ conical heads or sections, skirt/leg/lug/ring/saddle supports, nozzle

pipes, opening & connections, girth flanges, accessories and so forth, therefore a lot of facilities are ready for fabricating every type of pressure vessel.

Industrial Steel Structure & Commercial/Residential Building Frames

Manufacturing steel structures for

- Oil & gas refineries

- Petrochemical

- Power plant & chemicals industries,

- Pipe racks, roof structures, handrails

- Ladders / platforms

- Spiral & helical stairs,

- Commercial & residential buildings,

- Hospitals, bridges,

- Mezzanine, hangars,

- Heavy duties steel storages & warehouses

- Shelters and steel structures for factories.

Industrial Air Ducts

Industrial air duct systems are used for supply or exhaust, are under a positive or negative pressure, of heavy or light duty construction, convey clean and dirty airstreams, constructed of metal, plastic or fabric materials and assembled together with flanges, clamps, slip fit or welded. Duct systems include straight lengths or sections of duct, transitions, elbows and bends, enlargements or contractions, hoods, dampers, discharge stacks and hangers or supports.

Pipe Fabrication and Installation

In many instances, piping systems need to be rather substantial in size and quite complex in their design; and this is where companies in the energy industry can benefit from the expert pipe fabrication & installation services offered by ACGC.

Stated succinctly, pipe fabrication and installation are the method/process of manufacturing pre-designed piping systems to suit customer needs in relation to their individual businesses, facilities, and/or industries.

ACGC can produce pre-designed piping systems of all diameters and wall thicknesses. The systems are composed primarily of carbon steel or stainless steel and are assembled using the most efficient and appropriate welding procedures, selected from an extensive library of standards and specifications established by the American Society of Mechanical Engineers (ASME).